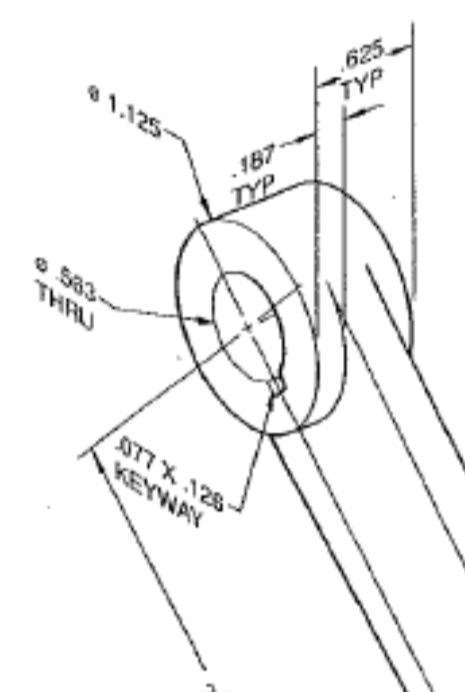

Corresponding keyways for Metric shafts are listed below in Table 2. The common specification dimension, Key Size, is highlighted. Metric Standard Parallel Keyway and Key Sizes Shaft Diameter (mm) Keyway (mm) Key (mm). From To Width (W) Depth (h) Width (W) Depth (T) 6 8 2 1.0 2 2 9 10 3 1.4 3 3 11 12 4 1.8 4 4. Nominal Shaft Diameter ( A ) Bottom of Keyway to Bottom of Shaft ( B ) Keyway Width ( C ) Reference Depth ( D ) fractional decimal fractional decimal 3/8 0.375 0.322 3/32 0.0938 0.053 7/16 0.4375 0.386 3/32 0.0938.

- These two-axis and three-axis mills cut keyways, slots, pockets, or flats on shaft diameters of 1.5 to 24 inches (38 to 610 mm). They can be operated in any position, thanks to their sealed gear box lubrication. CONTACT A CLIMAX EXPERT KM3000 KEY MILL.

- Our shaft collars are easy to install and can save time and money, giving you a fix where disassembly might otherwise be required. You'll find flexible couplings in a range of styles and sizes, plus shaft locking devices that can be used as drop-in replacements for keyless bushings. We also carry woodruff keys, universal joints and shaft mounts.

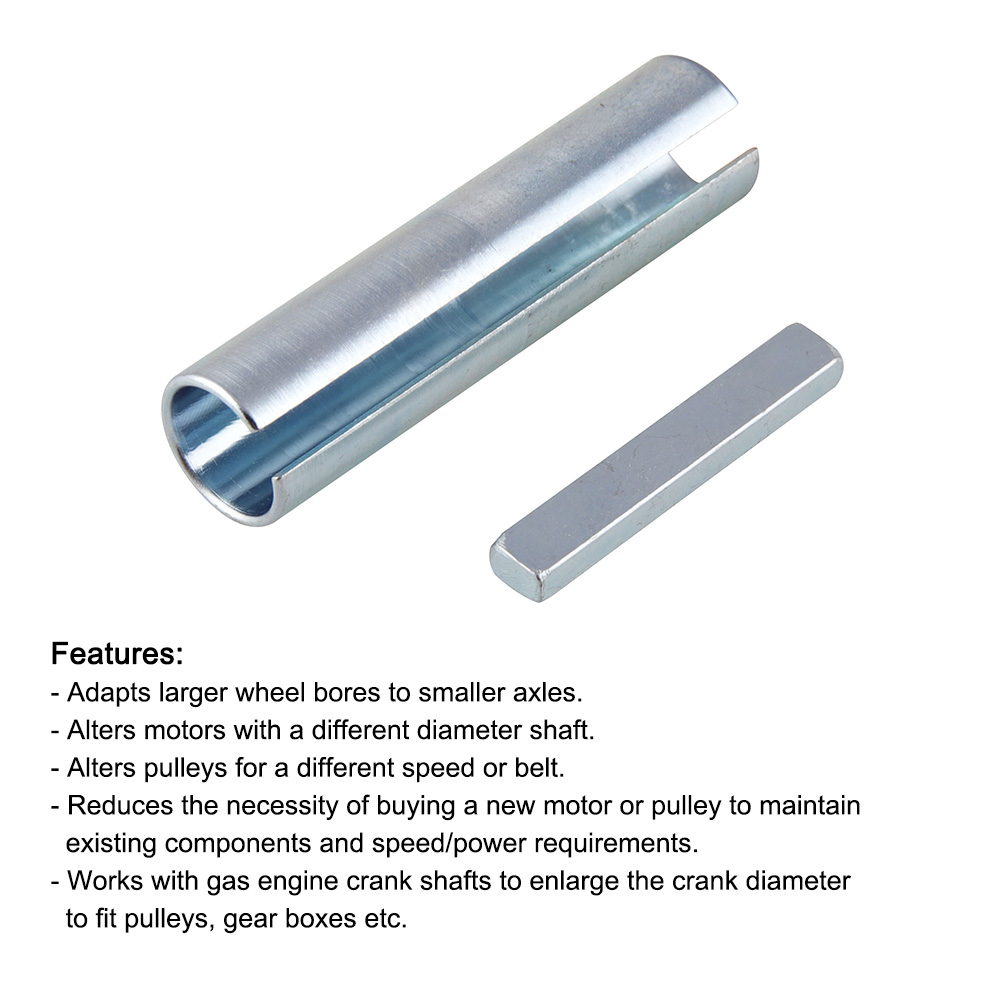

A keyway is a square channel machined into round a steel bar. The channel, or keyway, provides a place for a square piece of metal known as a key to lock a pulley or sprocket onto the round bar. The square key fits in both the keyway and a square slot machined into the sprocket or gear. By fitting securely between the round bar and the gear, the key creates a sturdy connection in the assembly. Typically, the keyway is machined into a piece of steel prior to any heat treating or hardening of the piece.

Many components utilize a keyway to produce a slip-proof method of attaching rotating parts. Axles, crank shafts and drive shafts all use a keyway to hold other components in place as they spin and provide power to drive other mechanisms. In some critical components such as propeller shafts, a special soft key stock is used that allows the key to shear off if it contacts a hard surface. By using a shear pin or key stock, damage to the shaft is eliminated as the propeller is allowed to spin free without damaging the shaft.

In automobile engines, the crankshaft has a keyway machined into the snout end that holds the harmonic balancer in position. All of the engine's accessories such as the alternator, air conditioning compressor and power-steering pump are driven off of belts that are powered by this balancer. Some of these accessories, such as the power-steering pump, commonly use a keyway machined into the pump shaft in order to hold the drive pulley in place as well.

Typically offered in many sizes, the size of the channel in the shaft and the key must be properly matched. Failure to match the proper-sized key with the correct size channel would result in a sloppy fit between the gear or pulley and the shaft. Any resulting slop would eventually lead to a broken key or a damaged gear, pulley or shaft. There are also different keyway styles that can be used for different applications.

While the square key stock is the most commonly used key material, half-round keys are used in many engine key applications. This half-round style of key is popular in applications where the entire key is placed underneath a single gear or pulley. With this key, the shaft is milled to receive the round portion of the key. The remaining key emerges from the shaft as a flat and square key that slides into the groove of a gear or pulley.

In this article we will see the basic difference between slot , holes, groove, and keyways.

1. Hole: circular cutout, either through the material or to a blind depth.

Types of Hole :

They are different types of holes that are mentioned below.

1.Simple Hole

2.Counter board

3.counter sunk

4.Tapered

5.counter drilled.

2. Slot or Slotted Holes: an elongated hole. It is stretched in one direction but still has full radii on the ends. A slot is cut into a flat plate or normal to the axis of a cylinder.

Slot Hole Design Consideration :

Slotted holes are widely used in most sorts of mechanical design. Apply mainly in precisely fine-tuning for uncontrollable dimensions beforehand, alignment accuracy, fixation in certain direction meanwhile keeping slipping free in other directions, and so on. Such as tension device of belt pulley, thermal stress protection for slender bar structural parts or long spindle shafts, alignment accuracy in complex dimension chain, a mechanism for enhancing tolerance, and eliminating accumulated error.

In mechanical design, some principles and factors we should take into account include the shape and travel of the slotted holes, the structural strength affected by the holes, and so on. In actual application, they can be classified into the following types: singleton slotted holes, coupled slotted holes.

Slotted Holes Slotted holes can be dimensioned in several different ways.

a. Center points on the longitudinal axis are located and the radii are indicated with a note.

b. Linear measurements indicate the overall size of the slot and the radii are specified.

c. A note indicates the two linear dimensions of the slot and another note specifies the radii.

Choose the most appropriate technique for sizing the slotted hole. The technique used for sizing the slot determines how the slot is located.

See Also: What is Slotting Machine- Principal parts of Slotter Machine

Shaft Keyway Size

3. Groove:a groove is a cylindrical slot. Grooves are cut around the OD or ID of a cylinder and do not pass through the axis of the cylinder.

Shaft Keyway Slot Tool

You can simply understand that a slot can be through or blind but a groove is always blind.

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material, generally for the purpose of allowing another material or part to move within the groove and be guided by it.

Examples include:

- A canal cut in a hard material, usually metal. This canal can be round, oval or an arc in order to receive another component such as a boss, a tongue or a gasket. It can also be on the circumference of a dowel, a bolt, an axle or on the outside or inside of a tube or pipe etc. This canal may receive a circlip an o-ring or a gasket.

- A depression on the entire circumference of a cast or machined wheel, a pulley or sheave. This depression may receive a cable, a rope or a belt.

- A longitudinal channel formed in a hot rolled rail profile such as a grooved rail. This groove is for the flange on a train wheel.

4. Keyway:

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint.

Vip deluxe slots free chips. Read More: Types Of Mechanical Keys- Design Of Keys.

Corresponding keyways for Metric shafts are listed below in Table 2. The common specification dimension, Key Size, is highlighted. Metric Standard Parallel Keyway and Key Sizes Shaft Diameter (mm) Keyway (mm) Key (mm). From To Width (W) Depth (h) Width (W) Depth (T) 6 8 2 1.0 2 2 9 10 3 1.4 3 3 11 12 4 1.8 4 4. Nominal Shaft Diameter ( A ) Bottom of Keyway to Bottom of Shaft ( B ) Keyway Width ( C ) Reference Depth ( D ) fractional decimal fractional decimal 3/8 0.375 0.322 3/32 0.0938 0.053 7/16 0.4375 0.386 3/32 0.0938.

- These two-axis and three-axis mills cut keyways, slots, pockets, or flats on shaft diameters of 1.5 to 24 inches (38 to 610 mm). They can be operated in any position, thanks to their sealed gear box lubrication. CONTACT A CLIMAX EXPERT KM3000 KEY MILL.

- Our shaft collars are easy to install and can save time and money, giving you a fix where disassembly might otherwise be required. You'll find flexible couplings in a range of styles and sizes, plus shaft locking devices that can be used as drop-in replacements for keyless bushings. We also carry woodruff keys, universal joints and shaft mounts.

A keyway is a square channel machined into round a steel bar. The channel, or keyway, provides a place for a square piece of metal known as a key to lock a pulley or sprocket onto the round bar. The square key fits in both the keyway and a square slot machined into the sprocket or gear. By fitting securely between the round bar and the gear, the key creates a sturdy connection in the assembly. Typically, the keyway is machined into a piece of steel prior to any heat treating or hardening of the piece.

Many components utilize a keyway to produce a slip-proof method of attaching rotating parts. Axles, crank shafts and drive shafts all use a keyway to hold other components in place as they spin and provide power to drive other mechanisms. In some critical components such as propeller shafts, a special soft key stock is used that allows the key to shear off if it contacts a hard surface. By using a shear pin or key stock, damage to the shaft is eliminated as the propeller is allowed to spin free without damaging the shaft.

In automobile engines, the crankshaft has a keyway machined into the snout end that holds the harmonic balancer in position. All of the engine's accessories such as the alternator, air conditioning compressor and power-steering pump are driven off of belts that are powered by this balancer. Some of these accessories, such as the power-steering pump, commonly use a keyway machined into the pump shaft in order to hold the drive pulley in place as well.

Typically offered in many sizes, the size of the channel in the shaft and the key must be properly matched. Failure to match the proper-sized key with the correct size channel would result in a sloppy fit between the gear or pulley and the shaft. Any resulting slop would eventually lead to a broken key or a damaged gear, pulley or shaft. There are also different keyway styles that can be used for different applications.

While the square key stock is the most commonly used key material, half-round keys are used in many engine key applications. This half-round style of key is popular in applications where the entire key is placed underneath a single gear or pulley. With this key, the shaft is milled to receive the round portion of the key. The remaining key emerges from the shaft as a flat and square key that slides into the groove of a gear or pulley.

In this article we will see the basic difference between slot , holes, groove, and keyways.

1. Hole: circular cutout, either through the material or to a blind depth.

Types of Hole :

They are different types of holes that are mentioned below.

1.Simple Hole

2.Counter board

3.counter sunk

4.Tapered

5.counter drilled.

2. Slot or Slotted Holes: an elongated hole. It is stretched in one direction but still has full radii on the ends. A slot is cut into a flat plate or normal to the axis of a cylinder.

Slot Hole Design Consideration :

Slotted holes are widely used in most sorts of mechanical design. Apply mainly in precisely fine-tuning for uncontrollable dimensions beforehand, alignment accuracy, fixation in certain direction meanwhile keeping slipping free in other directions, and so on. Such as tension device of belt pulley, thermal stress protection for slender bar structural parts or long spindle shafts, alignment accuracy in complex dimension chain, a mechanism for enhancing tolerance, and eliminating accumulated error.

In mechanical design, some principles and factors we should take into account include the shape and travel of the slotted holes, the structural strength affected by the holes, and so on. In actual application, they can be classified into the following types: singleton slotted holes, coupled slotted holes.

Slotted Holes Slotted holes can be dimensioned in several different ways.

a. Center points on the longitudinal axis are located and the radii are indicated with a note.

b. Linear measurements indicate the overall size of the slot and the radii are specified.

c. A note indicates the two linear dimensions of the slot and another note specifies the radii.

Choose the most appropriate technique for sizing the slotted hole. The technique used for sizing the slot determines how the slot is located.

See Also: What is Slotting Machine- Principal parts of Slotter Machine

Shaft Keyway Size

3. Groove:a groove is a cylindrical slot. Grooves are cut around the OD or ID of a cylinder and do not pass through the axis of the cylinder.

Shaft Keyway Slot Tool

You can simply understand that a slot can be through or blind but a groove is always blind.

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material, generally for the purpose of allowing another material or part to move within the groove and be guided by it.

Examples include:

- A canal cut in a hard material, usually metal. This canal can be round, oval or an arc in order to receive another component such as a boss, a tongue or a gasket. It can also be on the circumference of a dowel, a bolt, an axle or on the outside or inside of a tube or pipe etc. This canal may receive a circlip an o-ring or a gasket.

- A depression on the entire circumference of a cast or machined wheel, a pulley or sheave. This depression may receive a cable, a rope or a belt.

- A longitudinal channel formed in a hot rolled rail profile such as a grooved rail. This groove is for the flange on a train wheel.

4. Keyway:

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint.

Vip deluxe slots free chips. Read More: Types Of Mechanical Keys- Design Of Keys.